Chip Resistor Designed for High-Voltage EV Applications

The RVCA thick film, high-voltage chip resistor series from Stackpole Electronics is AEC-Q200 qualified and designed for the demanding requirements of 400 V and 800 V EV powertrain applications.

The RVCA from Raleigh, N.C.-based Stackpole Electronics Inc. is a thick film, high-voltage chip resistor series designed to meet the application requirements of the most demanding 400 V and 800 V electric vehicle (EV) powertrain buses.

EV powertrains operate up to 800 V. Image used courtesy of TI

The RVCA series is AEC-Q200 qualified and meets industry standard test requirements for load life, biased humidity, short time overload, and temperature cycling, making it well suited to the rigorous demands of high-voltage automotive applications.

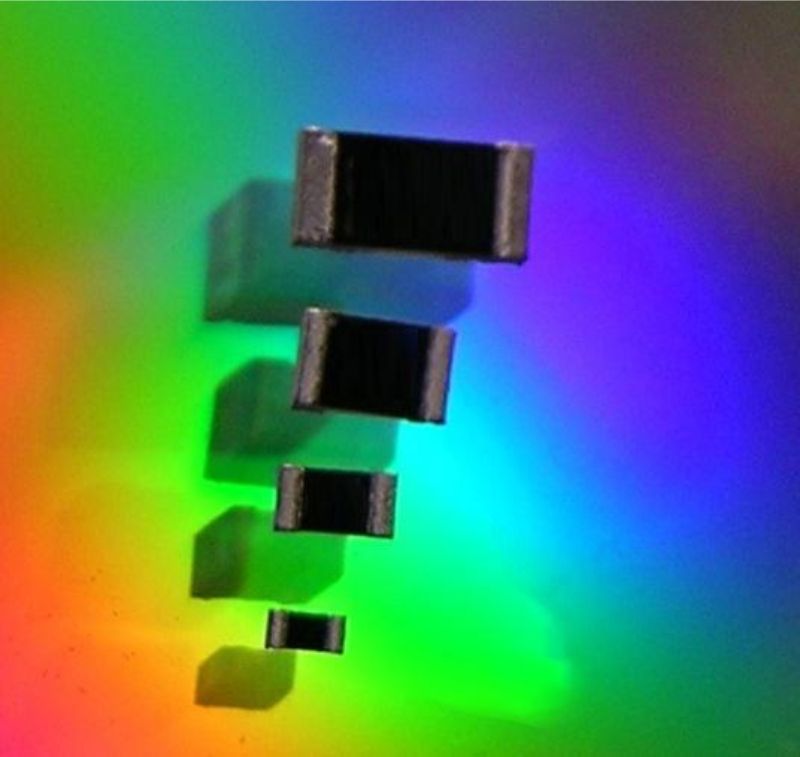

The chip-scale, surface-mountable resistor series consists of six models with operational voltage ratings from 100 V to 3000 V and is available in standard resistor package sizes ranging from 0402 to 2512. Parts are available with nominal resistance values ranging from 30 kΩ to 100 MΩ and specified to 1% or 5% tolerances.

High-Voltage EV Powertrain Monitoring and Control Circuits

High-voltage resistors like the RVCA series play an important role in the many monitoring, drive, and control circuits that operate within and across the isolation boundary of an EV high-voltage powertrain bus.

High-voltage switch monitoring circuit. Image used courtesy of TI

Applications include over/under voltage, short circuit, DESAT protection, gate-drive, temperature monitoring, self-test, and soft-start circuits.

Miller clamp for a high-voltage FET drive. Image used courtesy of TI

Pre-Charge Circuit for an EV Powertrain

Pre-charge circuits are another important application for high-voltage (and higher power) resistors in EVs. Motor inverters and similar loads connected to an EV’s high-voltage DC bus often have large input filter capacitors. During start-up, the initial charging of large circuit capacitances can lead to high in-rush currents (spikes of up to thousands of amps) that can damage electrical connectors and components.

Pre-charge circuit for an EV powertrain load (traction inverter). Image used courtesy of Sensata

As the name suggests, the pre-charge circuit helps to charge the input capacitance in a controlled manner. It does this by intelligently switching in a high-voltage series resistor with the input capacitance to extend the circuit time constant and limit the capacitor charge current.

Once the system detects that the load capacitance is sufficiently charged, the pre-charge resistor is removed from the circuit to allow for normal operation of the vehicle’s electric powertrain at optimal efficiency.

In addition to avoiding damage to the system and its components, a well-designed pre-charge circuit reduces normal operating stresses, increasing the operating life and reliability of the system.

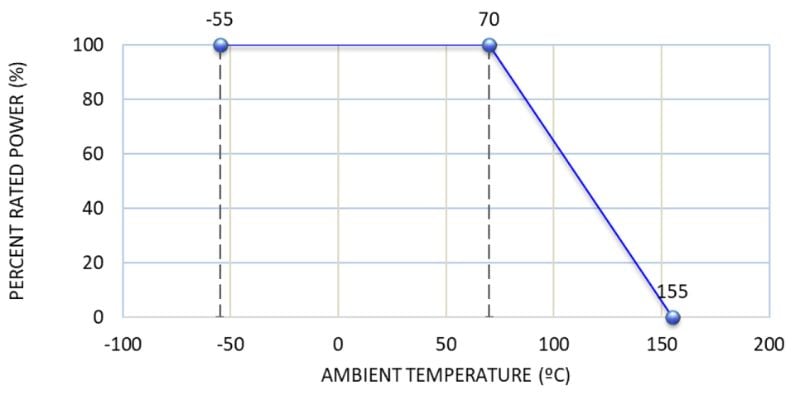

RVCA Power Performance

The largest RVCA series, the RVCA2512, has a power rating of up to 1 W at 70°C, a maximum operating voltage of 3000 V, and an overload voltage of 4000 V.

RVCA chip resistor power derating curve. Image used courtesy of Stackpole Electronics

Power dissipation capabilities derate linearly from 70 to 155°C.

RVCA series thick film, high-voltage chip resistor. Image used courtesy of Stackpole Electronics.

The 2512 package is nominally 6.35 mm x 3.1 mm with a height of 0.55 mm, and all of the chip resistor models are surface mountable for high-volume PCB manufacturing.

.jpg)