Could Cylindrical Batteries Become Standard for All EVs?

A growing number of companies are coming on board with 4680 high-capacity lithium-ion cells.

One would think all electric vehicles (EVs) would have standardized the configuration of their traction batteries. In theory, reducing the various types of battery cells should reduce costs and increase reliability.

Yet, the lithium-ion cells powering EVs come in configurations ranging from soft-sided pouches to hard plastic prismatic boxes and cylindrical cells in several dimensions. Each EV manufacturer, working with its battery supplier, has a reason for the cell configuration choice and will steadfastly justify its decisions.

Cylindrical batteries power the Tesla electric vehicle. Image used courtesy of Pexels

18650 Cylindrical Batteries

Among the types of lithium-ion battery cells growing in popularity are those in a cylindrical configuration. One early adopter of small cylindrical cells was Tesla—its original Roadster sports car in 2006 had 6,800 cells of the 18650 configuration (18 mm in diameter and 65 mm long, or slightly larger than a familiar AA cell battery). By the time the mainstream Tesla Model S hit the market in 2012, those 18650 cells were being made by Panasonic with as many as 7,728 cells in a 90 kilowatt-hour (kW-hr) pack. The 18650 cylindrical cells have been the workhorse for Tesla throughout its model range.

Why Cylindrical Batteries?

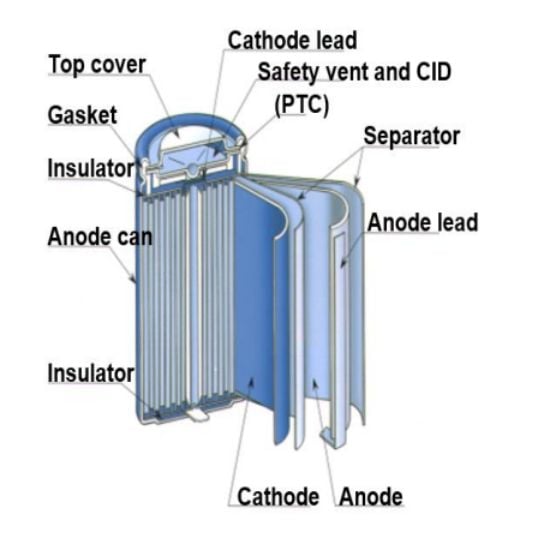

In many ways, cylindrical cells are the easiest to manufacture using highly automated equipment. The cell’s anode (negative electrode), cathode (positive electrode), and separators are sandwiched together as a sheet rolled up and placed into a cylindrical casing. The cylindrical cells offer high capacity and current discharge capability across a wide temperature range.

Structure of a cylindrical battery. Image used courtesy of the Department of Energy

Although packaging thousands of individual cylindrical cells poses challenges, their small individual size allows some flexibility in the battery pack configuration. Smaller cylinders also allow spaces between the cells to aid in their cooling.

21700 Cylindrical Battery

In 2017, Tesla and Panasonic began production of the 21700 cylindrical cells. Slightly larger than the 18650 cells, with a 21 mm diameter and 70 mm length, the larger size permits an increase in the area of both the anode and cathode sheets, allowing these cells to store more energy than the smaller cells. The downside is the larger anode and cathode sheets increase the path length over which the charge has to travel, increasing resistance and resulting in more energy lost to heating during charging and discharging. The 21700 (which Tesla calls the 2170) is found in the Tesla Model 3 and the company’s Powerwall battery storage system.

Tesla cylindrical batteries. Image used courtesy of Wikimedia Commons

The 4680 Battery Cell

Tesla unveiled its 4680 (46 mm diameter and 80 mm long) cell in 2020, and its higher capacity is important for the company’s products like the Cybertruck and Semi. Although the larger anode and cathode sheets would ordinarily create longer charge paths and more resistance, a new “tables” connection design compensates for this by reducing the cells' overall resistance.

The greater capacity of the individual 4680 cells allows fewer cells to be used, creating more power in the same size pack as earlier 18650 and 21700 cell configurations. With 4680 cells, about 960 cells fill the same space as the 4,416 of the 2170 cells, with a significant increase in power and lower cost per kWh. Tesla uses the 4680 cylindrical cells in the Tesla Model Y and the Cybertruck, both produced in Texas.

Enter The Other Batteries

Tesla and Panasonic are not the only companies recognizing the advantages of switching to 4680 cells. Korean battery giant LG Energy Solution (LGES) is known to be working on 4680 cells and will start production at its Ochang plant in South Korea in August 2024. The company also plans to begin producing the high-capacity cells at its plant under construction in Arizona, which will come online in 2025. In addition, LGES might begin 4680 cell production in its Nanjing factory in China, where it already produces 2170 cells for the Tesla Model 3 and Model Y built in China.

Other EV manufacturers are considering 4680 cylindrical cells for future offerings. So, leading battery companies like Panasonic and Contemporary Amperex Technology Co. Limited are developing their own versions to meet the demand. The 4680 might finally become the standard lithium-ion battery configuration for all future EVs.