Purdue University Researchers Find New Battery Technology

A research team at Purdue University uses microwave irradiation to recycle waste PET into a low-cost, environmentally friendly battery anode material.

Purdue University’s Research Foundation Office of Technology Commercialization operates one of the leading technology transfer programs among top-ranking universities within the United States. Researchers from Purdue have created a new battery technology that could make a significant contribution to renewable energy conversion and energy storage.

There is a burgeoning need to innovate within the arena of renewable energy technologies and solutions. One effective solution, Purdue researches have found, can be the recycling of used materials to reduce chemical effluence from manufacturing, production, and transportation.

Researchers at Purdue have found a way to recycle waste polyethylene terephthalate (PET), a general-purpose thermoplastic polymer, into a component used in batteries. PET is one of the most common thermoplastic polymer resins and is used in a variety of ways including fibers for clothing, containers for liquids and foods, thermoforming for manufacturing, and in combination with glass fiber for engineering resins.

From PET to Disodium Terephthalate

The Purdue researchers used an ultrafast microwave irradiation process to turn PET flakes into florets of disodium terephthalate. This low-cost, environmentally benign end product is what can be used as battery anode material. Working with the Indian Institute of Technology and Tufts University, the Purdue team also tried to use their approach for lithium-ion and sodium-ion battery cells. Research published on the breakthrough battery technology was published in the ACS Sustainable Chemistry & Engineering.

Disodium terephthalate florets. Image courtesy of Purdue

“The applicability of the microwave technique on organic reactions has gained attention in recent times due to its advantage of the rapid reaction process,” said Vilas Pol, a Purdue associate professor of chemical engineering who has worked with the Purdue Research Foundation Office of Technology Commercialization to develop several battery technologies.

“We have accomplished the complete conversion of PET to disodium terephthalate within 120 seconds, in a typical household microwave setup”, Pol added.

The process of producing disodium terephthalate florets through the irradiation of PET with microwaves. Image courtesy of Purdue

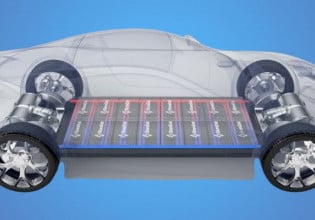

Due to a range of benefits, lithium-ion technology has been of deep interest to scientists and has dominated the portable electronics and electric vehicles market. Lithium-ion batteries have a high working voltage, large specific capacity, long life-cycle, low self-discharge rate, and are environmentally friendly.

Despite this, lithium reserve in the earth’s crust is limited while the demand for the material is high. In this scenario, other technologies such as sodium-ion batteries become another sensible option. They are low cost and exhibit appealing electrochemical performance in grid applications.

Using microwaves to make an anode material like disodium terephthalate not only promotes waste reduction through recycling but may also contribute to improved electrochemical performance for lithium and sodium ion technologies.