LG Chem & STMicroelectronics Drive To Improve Battery Technologies For Hybrid Electric Vehicles

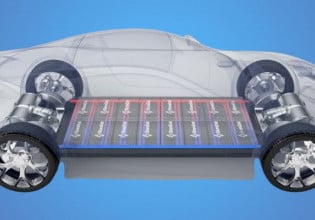

STMicroelectronics and LG Chem, described as the largest Korean chemical company, have unveiled details of a new automotive battery pack that is said to significantly extend the potential of electric and hybrid electric vehicles (HEVs), reducing both petrol consumption and CO2 emissions. The new battery pack combines LG Chem’s lithium ion (Li-ion) battery technology with a battery management chip manufactured by ST.

The new Li-ion battery pack from LG Chem manages the charge/discharge cycle by incorporating an advanced battery-management chip, manufactured by ST, which the company states enables safe and long-term reliability of Li-ion battery technology at affordable cost, even in applications as demanding as automotive powertrain systems.

"Accurate and reliable control of the battery charging and discharging cycles makes Li-ion technology applications the established choice for low-power consumer applications as well as a leading contender for future high-power," said Ph.D. MH Kim, the Vice President of the Battery Research Institute of LG Chem. "As the world’s number one supplier of power-management devices and one of the top suppliers of silicon chips to the automotive industry, ST was the natural choice to develop the silicon side of the battery pack to complement LG Chem’s advanced Li-ion battery technology."

ST’s battery-management chip is manufactured with the company’s proprietary BCD (Bipolar-CMOS-DMOS) technology, which combines digital logic circuits, precise analog measurement circuits and power-handling transistors in one silicon chip. A Battery Management System with these chips accurately controls the charging and discharging cycles of the battery to ensure safe operation and long battery life. Each chip can handle up to ten Li-ion cells and also includes an interface for communicating with other ST battery-management chips in a system. With this communication capability, as many as 32 battery-management chips can be connected in cascade to manage batteries that deliver up to 1600V to the electric motors.

"Reducing the consumption of fossil fuels and carbon-dioxide emissions is an integral part of ST’s product development strategy," said Marco Monti, General Manager, Power Train and Safety Division, Automotive Product Group, STMicroelectronics. "We are proud that we’ve been able to adapt our power management and analog expertise with LG Chem to create a new solution that will enable Li-ion batteries to address increasingly higher power applications, from e-bikes to the most demanding public transport vehicles."