SEG Automotive Revolutionizes Generator Efficiency with Semiconductor Technology

SEG Automotive was able to increase the efficiency of their automotive generators, thus decreasing carbon dioxide emissions.

SEG Automotive was able to increase the efficiency of their automotive generators, thus decreasing CO2 emissions.

While Electric Vehicles are growing at a rapid pace, fossil-fuel cars are still holding a steadfast grip on the market, projected to hold 85% of the share by 2025. With this in mind, designers looking to minimize our carbon footprint cannot only concern themselves with long term solutions like EV design but also immediate solutions like increasing the efficiency of combustion engine vehicles, resulting in lower carbon emissions.

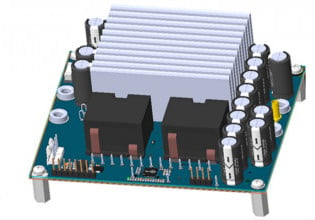

Image courtesy of SEG Automotive.

SEG Automotive was able to solve this immediate issue by changing the design of its electric generator. According to a recent press release, SEG Automotive was able to increase the efficiency up to 7 or 8 percentage points, which will make overall efficiencies of 80+% a reality, a ceiling unbroken prior to this. They were able to do this by replacing their normal rectifier circuit with an Active Rectifier.

The incredible part, however, is that this modification only requires the changing of a single part. The only change needed is to replace the normal diode within the circuit with an Active Rectifying Diode (ARD), which in reality is a MOSFET with a specified bias voltage. Due to a MOSFET’s lower forward resistance, it is able to reduce power loss due to the voltage drop across it, as it will then be lower than that of a normal diode. These MOSFETs need an active bias voltage circuit controlling it, hence its name as an Active Rectifying Diode, but with this will increase the efficiency of the overall circuit greatly.

This is not only an innovation that SEG Automotive will be rolling out in future vehicles, but they designed this new generator with the same dimensions and physical parameters as the original generator it will be replacing, so it can be used in a plug-and-play manner, taking out the old generator and immediately replacing it with the new one, providing lower emissions for cars on the road today.

Image courtesy of SEG Automotive.

The innovation yields a total savings of up to 1.8 g of CO2/km for fleet consumption, a great success for climate protection as well as a simple solution for manufacturers to meet the increasingly stringent CO2 emissions standards, especially in the EU. Overall, according to the CEO of SEG Automotive, Peter Sokol, based on their current demand for products, the new generators have the potential to save almost 1.2 billion liters of fuel and 3 million tons of CO2 over the lifecycle of the vehicles they are within, an astounding result from a minute design change.

These immediate solutions are a very important part in our fight against climate change. We cannot bank on future technologies to save us from the technology we continue to use every day, the problem will only get worse while we wait. SEG Automotive noticed this need and was able to find the simple solution to help solve it.

Overall, SEG Automotive reminds us that true engineering innovation does not aim to be complex, but the best engineering innovations are the ones that are simple, and, in the case of combustion engines that have not had any major changes in 100 years, the simple solutions are usually the hardest to find.