Silicon Anode Offers Cheaper EV Batteries With Longer Range

A battery materials startup unveiled anode technology to reduce the cost of lithium-ion batteries while maintaining electric vehicle range.

The electric vehicle (EV) battery dictates its range and performance, but it’s also the EV’s most expensive component. Battery manufacturers face various obstacles, such as a scarcity of raw materials. Consequently, EVs are priced higher than their fuel-powered counterparts, discouraging widespread adoption. To surmount this obstacle, it is crucial to innovate battery technology incorporating cost-effectiveness and long-range using abundantly available raw materials.

Battery startup Coreshell claims it has discovered a method to manufacture cheaper lithium-ion batteries for long-range EVs. This article examines the challenges facing the widespread adoption of EVs and explores how Coreshell’s approach could provide a solution.

Electric vehicle batteries. Image used courtesy of Department of Energy

Decoding the Battery Materials Dilemma

Important raw materials used in EVs include lithium, cobalt, graphite, and nickel. While these materials are needed for a wide range of contemporary technologies, not just EVs, geopolitical factors have limited their global availability.

To date, China accounts for more than half of the world's lithium production. The United States processes only a small percentage of the lithium mined in China, Australia, and Chile. China is predicted to continue leading the world in lithium-ion battery manufacture through 2026. The limitations pose difficulties and fear of rising raw material costs in the EV market.

Electrodes are critical components of lithium-ion batteries, as they are central to storing and releasing ions for electrical energy. Graphite, a typical material used in battery anodes, provides stability and allows limited lithium ions to be held inside its layers. In comparison, silicon, another potential electrode material, can absorb more lithium ions, which enables it to store more energy. Yet, silicon tends to expand and contract during charging and discharging, which can cause the battery to degrade over time.

Degradation of lithium-ion battery. Image courtesy of ResearchGate

Engineers are trying to solve the conflict between graphite's stability and silicon's greater energy storage capacity for the best battery performance. Addressing silicon-related challenges could alleviate raw material shortages, reduce battery costs, and enhance EVs' overall performance.

Breaking Barriers With Silicon Anodes

Coreshell, a battery materials startup, claims it has developed a method to produce cheaper lithium-ion batteries without compromising performance. The breakthrough involves utilizing metallurgical-grade silicon, 50% less expensive than graphite, as an anode material in lithium-iron-phosphate (LFP) batteries.

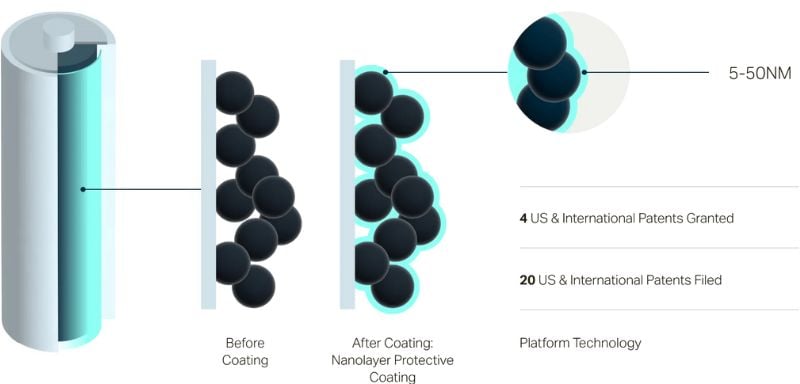

By leveraging a proprietary coating for the silicon anode, Coreshell seeks to mitigate the structural degradation caused by the significant volume expansion of silicon during charging cycles. When paired with LFP cathodes, the company's silicon anodes could offer a competitive advantage over traditional graphite anodes, bridging the energy storage gap between LFP and nickel-manganese-cobalt (NMC) chemistries. LFP cathodes provide cost-effective safety advantages over chemistries like NMC in EVs, with ingredients more available beyond China. The company predicts the combination of LFP cathode and silicon anode could be a game changer for battery technology and LFP.

Coreshell’s coating technology. Image used courtesy of Coreshell

Because silicon boasts greater energy storage capacity, batteries with equivalent capabilities require less material than those using graphite. Furthermore, Coreshell anticipates the United States will have ample metallurgical silicon to satisfy demand, further enhanced by its lower cost than graphite. This suggests the potential for metallurgical silicon to displace Chinese graphite in battery manufacturing.

Charging Ahead With EV Batteries

Coreshell's current breakthrough in utilizing metallurgical silicon for lithium-ion batteries shows promise in addressing raw material scarcity and reducing costs in the EV sector. This innovation holds significant implications, potentially reshaping the industry's landscape toward affordable electric mobility. With potential geopolitical implications and the prospect of cheaper batteries, the industry awaits scaled-up production.