Blocking Bolts: Blade Coating Steps Up Lightning Protection

Arctura signs a technological license agreement with Mankiewicz to introduce lightning protection coating for wind turbines.

Wind energy has emerged as the fastest-growing renewable energy source globally. Wind power offers a cheaper and cleaner alternative to fossil fuels, as it generates no greenhouse gas emissions or other pollutants. However, harsh weather conditions pose a significant challenge to the integrity and operation of wind power turbines, thus affecting the reliability of this renewable energy source.

In a recent development, renewable energy company Arctura partnered with coating manufacturer Mankiewicz to combat lightning damage in wind turbines. This article explores the challenges in adopting renewable energy sources and investigates the company’s promising development to overcome these obstacles.

Lightning hitting wind turbines. Image used courtesy of Unsplash

Wind Power Generation Challenges

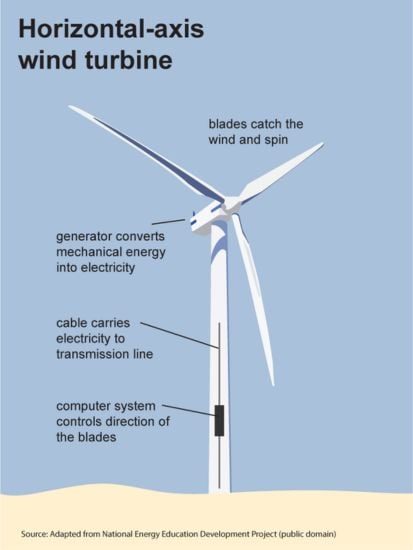

Wind turbines capture wind energy by converting its kinetic energy into electrical power. This process involves an alternator within the turbine, which transforms the rotational energy into electricity. In offshore wind turbines, the generated power is transmitted through a subsea cable to an offshore platform, where it is combined with electricity from adjacent turbines. After voltage amplification via a transformer, the electricity is transmitted through a larger subsea cable to the mainland. At the shore station, the power undergoes conditioning before integration into the national grid for distribution across the country.

Wind energy generation. Image used courtesy of Energy Information Administration

These turbines serve as pivotal components in renewable energy frameworks, yet they encounter numerous hurdles arising from natural phenomena. Adverse weather phenomena, such as strong winds, storms, lightning, ice, and snow, pose threats to turbine integrity, diminish power generation, and escalate maintenance expenses. In particular, a lightning strike on an unprotected wind turbine blade can lead to devastating consequences like temperatures soaring to a staggering 54,000°F (30,000°C), causing an explosive expansion of air within the blade. This can result in delamination, surface damage, melted adhesives, and cracks along the leading and trailing edges. It is a harsh reminder of nature's power and the importance of protecting wind turbines from such destructive forces.

Lightning strikes on wind turbines pose a significant challenge to the wind energy industry, costing well over $100 million annually. Mitigating this risk requires innovative lightning protection systems and advanced materials engineering to ensure the integrity and reliability of wind turbine operations.

Addressing Hurdles in Wind Turbine Technology

To solve these issues, Arctura recently unveiled its landmark collaboration with Mankiewicz, a pioneer in cutting-edge coating solutions.

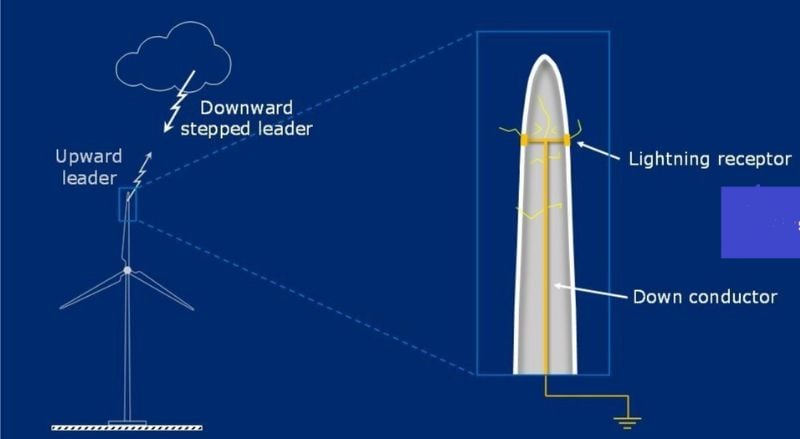

Common lightning protection systems use receptors connected to a down conductor. Lightning begins with an upward leader from the receptors, and a direct strike occurs when it connects with a downward leader from the cloud, passing a large amount of power through the turbine. The issue arises when streamers form from the down conductor or other metallic parts within the blade. These streamers often develop into leaders that link with the downward leaders from the cloud, resulting in a strike that can destroy the blade.

As wind turbine manufacturers continue to construct taller turbines and lightning activity increases due to climate change, the problem is expected to be exacerbated. The ArcGuide coating addresses this issue by enhancing the performance of installed lightning protection systems. This polyurethane-based topcoat, incorporating a proprietary mixture of discrete elements, facilitates the formation of ionized channels over the turbine blade surface during lightning strikes. These channels provide a safe path for the electrical discharge to reach the ground receptor, preventing damaging blade punctures.

The lightning protection system. Image used courtesy of Arctura

Whenever lightning activity surrounds a wind turbine, competition occurs between the streamers forming inside the blade and those forming at the lightning receptors on the outside of the blade. The ArcGuide coating modifies the surface of the blade to make it more likely the streamers forming at the receptors will out-compete the interior streamers and be the first to connect with the lightning leaders.

Charting a Safer Course for Wind Power

According to the companies, this innovation works to enhance the performance of existing lightning protection systems and set the stage for further advancements in renewable energy technology. With more robust and resilient wind turbines, there is hope for a future where renewables are a primary source of energy without fear of downtime.