Advances in EV Battery, Charging Tech Take Off

Research from Oak Ridge National Laboratory investigates the battery needs of electric aircraft and expands wireless electric vehicle charging.

Oak Ridge National Laboratory (ORNL) is often at the forefront of cutting-edge science and engineering in electric vehicle technology. Two recent research projects targeted electric vertical take-off and landing (eVTOL) aircraft and EV wireless charging capabilities.

ORNL’s eVTOL research focuses on finding the optimal battery technology for the aircraft to meet variable power demands. Its wireless charging technology promises to charge a vehicle to 50% in less than 20 minutes.

VoloCity eVTOL. Image used courtesy of Wikimedia Commons

Unique Batteries Needed for eVTOLs

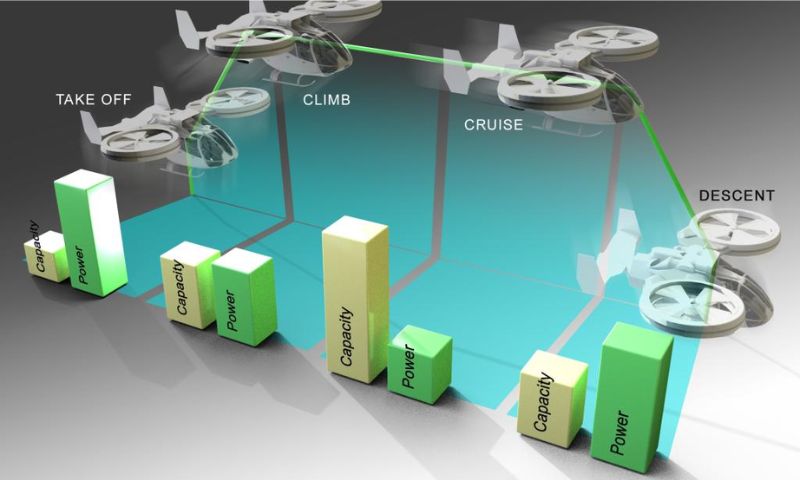

The trade-off between the rapid discharge and longevity of charge in batteries is always up for debate. While a standard and uniform discharge rate is fine for many applications, for eVTOL applications, the power requirements during take-off, climbing, cruising, and descent are different. This means batteries must be designed to meet these needs.

Standard lithium-ion (Li-ion) batteries used in most EVs cannot be adapted for eVTOL aircraft, as they don’t have the high discharge release required for take-off—at least, not safely. ORNL’s eVTOL program is looking to create an EV battery that can meet these aircraft's dynamic charge release conditions.

Stages of eVTOL operation. Image used courtesy of ORNL/by Andy Sproles

Li-ion batteries perform best when kept to a certain performance level over time. However, demanding high performance and rapid discharge significantly impacts their longevity and durability. ORNL used energy-dense materials to push Li-ion batteries to the extreme to see how much power could be extracted on demand to power eVTOLs at different flight stages.

The ORNL’s tests linked actual flight profiles to real-time battery operation—something not commonly achieved in battery testing. This approach revealed insights into how suitable (or unsuitable) current Li-ion technology is for eVTOL applications.

Most high-power lithium batteries currently have discharge rates of 2 to 5 times the nominal battery capacity (2C to 5C), and EV testing normally only goes up to 3C as this simulates normal driving conditions. However, eVTOL driving conditions are far from normal, so the researchers opted to put the battery under a significant electrochemical strain at 15 times the battery’s nominal capacity (15C) for 45 seconds. This was to simulate the average high-power demands of eVTOL batteries during take-off, which is much higher than the United States Advanced Battery Consortium guidelines. The peak power testing for EV applications is 5C for 30 seconds.

The tests showed that current battery systems are not up to the task and could not sustain the high discharge pulses for any extended cycling period. This led to the rapid failure of the batteries after the high discharge rates were reapplied.

The challenges with the current crop of battery systems led to ORNL developing a new electrolyte. While it’s still in the early stages, the electrolyte performed better, retaining more capacity during the most power-demanding flight phases. The researchers want to improve the electrolyte and other battery components, so there’s still promise for developing high-performance batteries that can meet the harsh power demands of eVTOLs.

Wireless Power Transfer to EVs

In other research, ORNL investigated wireless charging for EVs, this time cars. Charging capability is always at the heart of the EV debate. Many advanced technologies today have wireless charging capabilities, and EVs may have access to a similar level of technology in the near future.

Wireless charging can potentially eliminate wired charging at home and in public places. Drivers could park in a designated spot and charge their car, saving time and effort.

ORNL researchers have created a wireless charger using polyphase electromagnetic coupling coils with rotating magnetic fields. This charger allows light-duty passenger vehicles to be wirelessly charged at 100 kW with 96% efficiency. The researchers tested the charging capabilities on a Hyundai Kona EV. The coil system's diameter is only 14 inches, so it does not take up much space but still offers a great deal of power density compared to smaller coils.

ORNL’s wireless charging technology. Image used courtesy of ORNL/by Carlos Jones

In comparison, the average home EV charger is only 7 kW, and even rapid chargers used commercially are only 50 kW.

For passenger vehicles, the charger now has the highest energy density in the world and can reach power densities 8-10 times higher than conventional coil technology. The technology also increases the battery charge state by 50% in under 20 minutes. There’s currently a lot of potential for these wireless chargers, but nothing has been mentioned yet surrounding cost and the economics side of the development. So, the technology is there to be built upon and implemented, but we’ll have to wait and see if it’s at the right cost for EV users and owners of EV charging stations.