Innovative Remote Sense Approach for Power Supply Test & Measurement Systems Eliminates Potential Problems

This article discusses the advantages of using the innovative approach to Remote Sense for power supply test and measurement applications.

Remote sense is an effective voltage-regulation technique used in test and measurement applications and is often critical to achieving accurate and repeatable test results. A new and innovative approach to remote sense in programmable power supplies eliminates the remote sense wires – and all their potential noise problems.

Traditional Approach to Remote Sense

Remote sense is a well-established method for accurately regulating the DC power at the point of load by eliminating the effect of voltage drops in the connecting cables. This is particularly important in test and measurement applications where the accuracy and consistency of the power supply voltage over a range of load conditions is often critical to achieving accurate and repeatable test results.

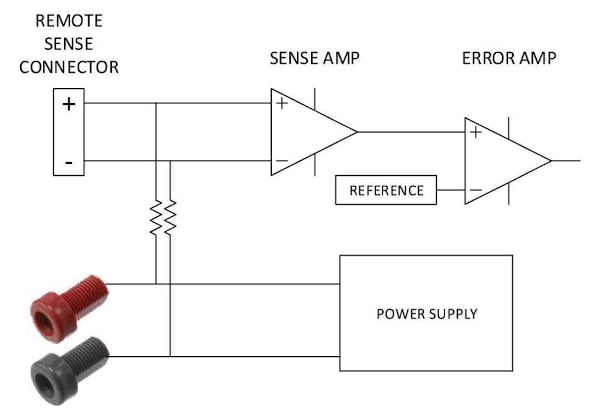

Figure 1 illustrates the sense arrangement in a power supply that does not use a remote sense connector. In this example, a high input impedance sense amplifier in the power supply, combined with an error amplifier, controls the output voltage as the load varies.

Figure 1: Basic power supply load regulation without remote sense

Figure 2 illustrates a power supply using a typical remote sense configuration. Remote sense tightly regulates the power supply voltage at the point of load by compensating for the voltage drop across the wiring connecting the power supply to the load. A power supply with conventional remote sense includes a second pair of (sense) leads that originate at the load and then are directly connected to power supply’s sense amplifier. Low value resistors, typically 10Ω to 100Ω, are used to connect the sense lines to the output terminals of the power supply. As long as the resistance of the sense wiring is much lower than these resistors, the sense amplifier will measure the voltage at the load. If no remote sense wires are connected to the load, then the sense amplifier is connected to the output via these low value resistors.

Figure 2: Power supply load regulation with remote sense compensates for voltage drop in the connecting leads

Drawbacks of Conventional “Wired” Approach

The conventional remote sense technique that depends on wires and connectors is fraught with potential problems – namely, noise interference in the remote sense lines and potentially damaging ground loops or reversed polarity connections. These drawbacks can limit its usefulness and accuracy. In addition, failure mechanisms associated with this topology frequently occur.

Injected Noise

A common problem with the sense leads used in remote sense is that they are long and prone to picking up noise from the environment. Any noise picked up by the sense leads will be amplified by the power supply. This can result in a noisy output, oscillation of the power supply or even failure of the power supply.

Care must be taken with the sense leads to avoid noise sources. The sense leads are often prescribed to be a twisted pair to minimize this problem. In some cases, the output leads of the power supply must be separated from the sense leads to eliminate problems. Small value resistors are typically used between the remote sense connector and the output, since if large-value resistors are used, the input impedance of the remote sense would be so high that the noise problem would be insurmountable. Unfortunately, the resistors cannot be made so small that there is no noise problem due to ground loop issues. In some cases, additional shielding of the remote sense wires is required in high noise environments.

Many power supply companies employing the typical approach to remote sense have had ongoing customer complaints and power supply failures that eventually were tracked back to injected noise issues.

Ground Loops

Ground loop problems are a common cause for the return and repair of many power supplies. Any power supply, and particularly high-current power supplies, can create a significant voltage drop in the wires connecting the output of the power supply to the load. This is the reason remote sense exists. Unfortunately, should the leads to the load be undersized or become accidentally disconnected, damage to the power supply internal remote sense circuit can result. This occurs because any drop across the load wires is reflected across the two series resistors that are necessary in the sense circuit. Should either load wire momentarily open, or should the drop in the load wires be sufficient, the sense resistors will conduct enough current to cause them to fail.

Reversed Polarity

Reversed polarity, unfortunately, happens all too frequently in applications. If, during setup, the remote sense leads are inadvertently connected in reverse, the destruction of the sense resistors is a highly probable outcome. The power supply’s overcurrent protection will likely limit the damage, but the sense resistors will most likely need replacement.

Benefits of New “No Wires” Approach

Most of the test and measurement power supplies on the market today are designed with analog control loops. Many have digital front panels and digital interfaces for the user but the actual control of the power supply is still done with analog circuits. Through full digital implementation, a programmable power supply can be controlled in many ways that are simply not possible with an analog control loop. The control loop can be changed in real-time, for instance, to accommodate many types of loads. Power supply performance can also be easily tailored to meet specific customer needs.

Figure 3: The Versatile Power Bench XR power supply uses patent pending digital remote sense to eliminate wires

In the case of remote sense, Versatile Power has developed a patent pending technique utilizing digital control to eliminate all the problems discussed above while providing additional benefits. With the Versatile Power BENCH XR power supply (Figure 3), no leads are required other than the power leads to the load, thus simplifying installation by eliminating the extra wires. This solution is just as accurate as wired remote sense without the associated risk.

Remote sense is accomplished by determining the resistance of the leads to the load. Once this data is known, then Ohm’s Law can be used to determine the voltage needed on the output of the power supply to get the proper voltage on the load. By applying the versatility of its digital control, the power supply can sense the output current and recalculate the output voltage requirement at the switching frequency of the supply. With this approach to remote sense, the power supply can respond to variations in the load current far faster than a wired remote sense scheme can.

Setup is very easy. First, the power supply is connected to the load. Then, using an automated calibration procedure, the power supply leads are shorted at the load. The power supplies’ digital signal processor then measures the lead resistance.

With this done, the short is removed from the load and the power supply will automatically compensate for any load variation. There is no possibility of picking up noise from sense wires. Also, there is no possible ground loop or reverse connections. And finally, there is no limit to the amount of load wire compensation voltage as there are no sense resistors that can be damaged.

About the Author

Dave Hoffman is President, Cofounder, and VP of Engineering at Versatile Power, which he launched in 2002 with CEO and co-founder, Jerry Price. Dave brings decades of innovative design and management experience to the organization and holds numerous patents. He has worked in the power electronics, medical device, and semiconductor industries for over 30 years. He is the visionary behind Versatile Power’s products, which focus on combining cutting edge technology with ease of use. Dave leads the company in its mission to create products that exceed customer expectations. He has a BSEE degree from California Polytechnic State University and has been granted 12 patents for his contributions in the power electronics field.

This article originally appeared in the Bodo’s Power Systems magazine.